We clean tanks in operation, with no confined space entry required

We clean tanks in operation, with no confined space entry required

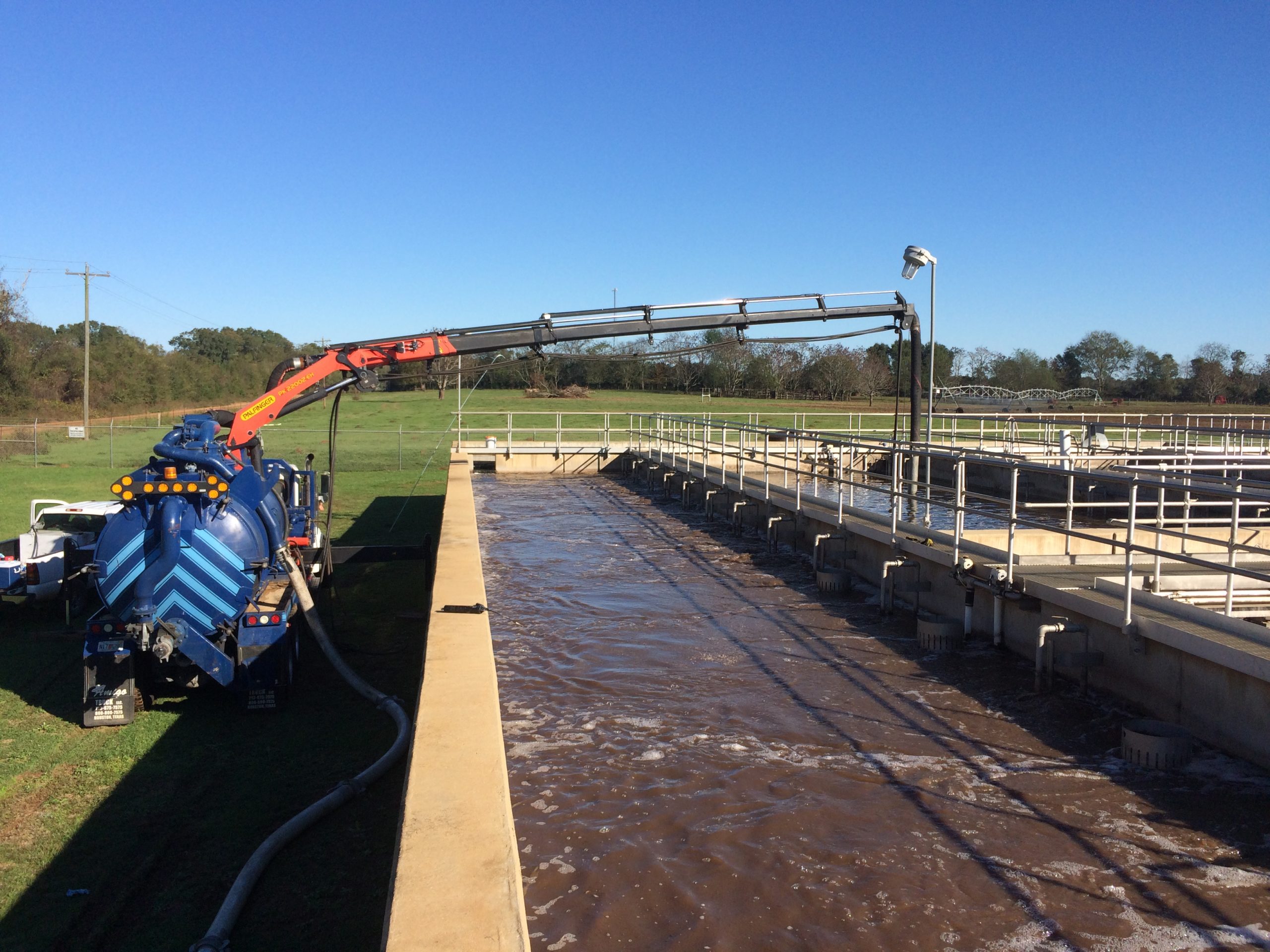

Cleaning tanks in submerged conditions while in operation is our specialty. If the infrastructure allows, we can clean tanks while in service, without the need to drain down structures, which keeps our crew out of confined space and allows us to solve problems that were previously very expensive to solve.

Tank depth and wall height are common constraints when it comes to removing sand and grit from tanks, chambers, basins, and more. If you’re facing high walls, we’ve got you covered. With the extended reach of our Combination3® equipment, even in drain down or dry conditions, we are able to achieve a high rate of production and can reach where others can’t.

Our Combination3® reaching into an aeration tank to perform cleaning without the need for shutdown.

Your obstacle

There are many types of tank structures used in a variety of ways in wastewater treatment systems, and they can all experience reduced capacity from the gradual accumulation of sand, grit, FOGs, rag material, vegetation, and more. Buildup of these types of material leads to increased energy costs and reduces overall plant efficiency.

Our Solution

U.S. Submergent Technologies cleans tanks in operation with no confined space entry required whenever possible. We can provide regular maintenance so facilities can avoid performing costly repairs or replacing expensive infrastructure. In addition, when cleaning in wet environments, our patented GritGone Process® results in paint-filter dry material, ready for disposal.

See, Clean, & Verify While in Operation

When visibility is crucial to the job ahead, USST’S CCTV/Sonar assessment and verification services allows us to see, clean, and verify the conditions of both tanks and pipes in real-time while in full operation with no bypass or facility shutdown.

CCTV Crawler in Action

Our technology allows us to preview sediment build-up, view sections of pipe that are in need of maintenance or repairs, and verify material removal after cleaning. The technology gives us greater visibility and better prepares us for the project, ensuring a more tailored solution and a quicker outcome.

- Live inspection feed in submerged conditions

- Comprehensive pre-and-post cleaning inspection video and reports

- Both CCTV Crawler or Combined CCTV/Sonar imaging capabilities available as needed

- Recommendation for best course of action for removal of material

- PACP Certified Operators

- Ready to deploy upon notice

Being able to reach and remove what others can’t is our specialty.

Tanks we clean

- Aeration Basin

- Anoxic Tank

- Backwash Basin

- Clarifier

- Chlorine Contact Chamber

- Digester

- Effluent Channel

- Equalization Basin

- Grit Chamber

- Gypsum Pond

- Headworks

- Influent Channel

- Lagoon

- Methane Tank

- Oxidation Ditch

- Package Plant

- Pond

- Reject Pond

- Sand Filter

- Sediment Trap

- Sludge Tank

- Splitter Box

- Storage Tank

- Surge Chamber

- Trickling Filter