Wastewater Visibility News

Lift Station Maintenance Made Easy

Lift Station Maintenance Made Easy

REDUCE THE RISK OF SANITARY SEWER OVERFLOW IN WET WELLS

Wet well and lift station maintenance are a frequent source of concern for most wastewater collection systems. Performing regular maintenance can be difficult due to access challenges, costs associated with shutting down pumps, and confined space entry permitting and safety issues.

Wastewater systems rely on lift or pump stations to transport collected wastewater to a treatment plant. Lift or pump stations typically include two to three pumps for redundancy — all of which require periodic inspection and maintenance. More often than not, a wastewater facility may only have one operable pump. Additionally, the water elevation in a wet well cannot be lowered in high-flow conditions such as heavy rain periods or during tourist seasons. With one operating pump, traditional maintenance can seem nearly impossible.

However, in order to reduce pump run time, reduce energy costs, and prevent debris from accumulating and creating new issues downstream, lift station maintenance is critical.

Performing regular lift station maintenance reduces the risk of sanitary sewer overflow (SSO), a scenario where untreated wastewater is discharged from a sewer into the environment before reaching a wastewater treatment facility. SSO can have extremely negative consequences for the environment and population in the areas surrounding the overflowing wet well.

Lift stations also accumulate a lot of sand and grit via inflow and infiltration, reducing the capacity of a wet well. The more debris in the wastewater collection system or lift stations, the more frequently the pumps must start and stop due to reduced cycle times. When sand and grit accumulates in a wet well or a lift station relies on only one working pump, the risk of SSO is increased.

Restore wet well capacity easily and safely with the Combination3® Truck.

U.S. Submergent Technologies developed a new solution to restore the capacity of wet wells while they remain in full operation and with little to no confined space entry.

The Combination3® Truck has all the tools necessary for wet well maintenance incorporated into one piece of equipment, and the truck’s 49-foot reach solves most access issues. The jetter has the ability to clean the structure, and the vacuum removes material such as fats, oils and greases. The truck’s downhole pump removes sand and grit from the wet well while the lift or pump station remains in full operation, without the need for confined space entry.

U.S. Submergent Technologies’ ability to quickly switch between vacuuming and downhole pumping on the spot significantly increases production rate by having the right tool for the job immediately on call. While a typical vacuum truck must wait for a low-flow period, the Combination3® Truck can operate when a lift station is at full capacity.

Using our GritGone Process® to complete the project generates paint-filter dry sand, ready for disposal.

The U.S. Submergent Technologies crew complies with OSHA confined space regulations, maintains proper ventilation, and measures atmospheric conditions. The crew members have all received required health and safety training, and our team completes more than 40 hours of position-specific training with an experienced field supervisor, including space safety and awareness, fall protection, first aid training and more.

U.S. Submergent Technologies’ goal is to get the job done in the safest and most efficient way possible. Contact one of our qualified representatives to learn more about our wet well and lift station cleaning and inspecting capabilities at (844) 765-7866 or click here.

Author Notes

Wastewater Visibility News

More Recent Posts

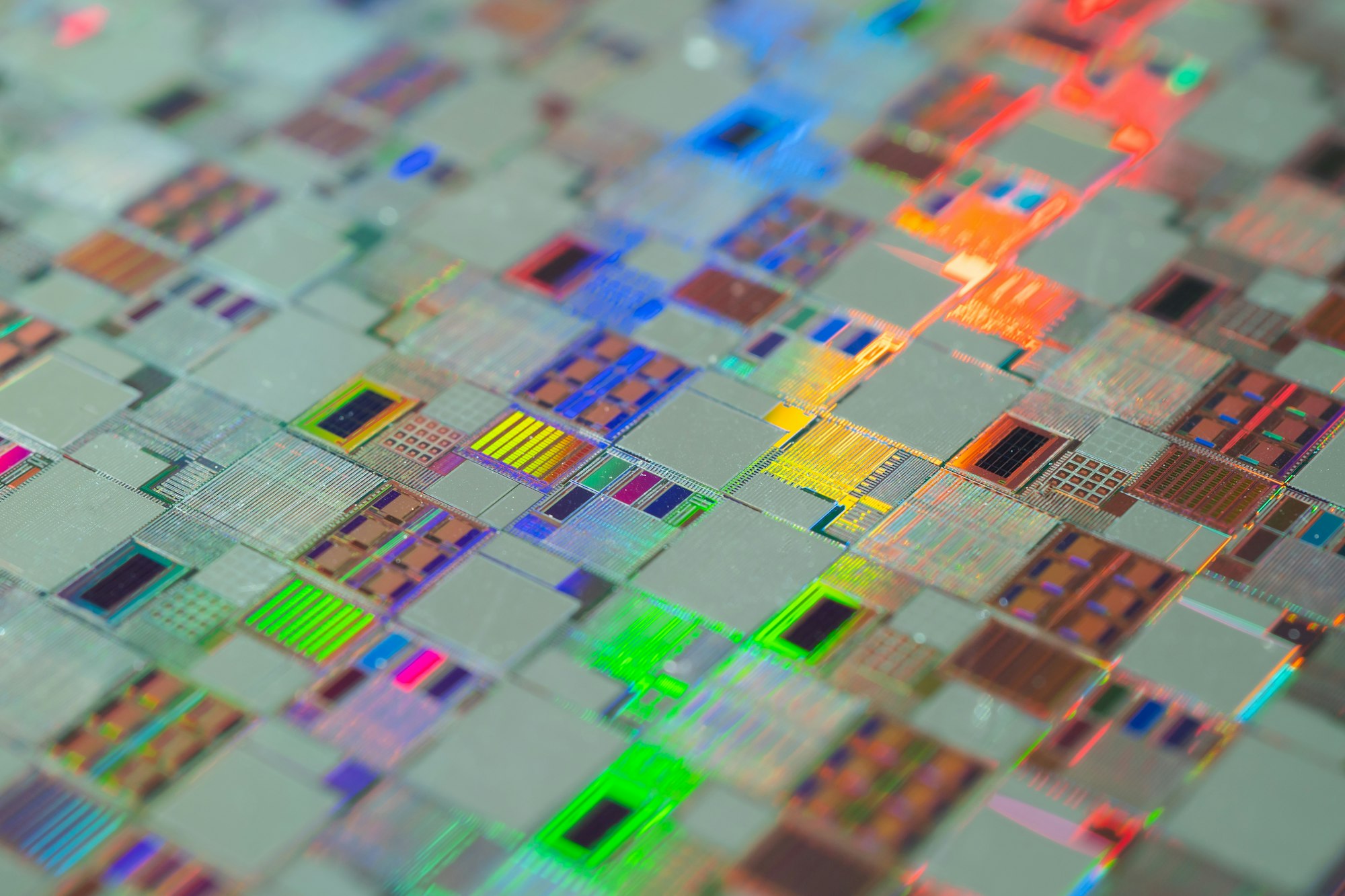

105.668 Gallons of Wastewater to be Reused Daily in the Manufacture of Semiconductors

First-Ever National Drinking Water Standard to Protect 100M People from PFAS Pollution

Are Your Wastewater Tanks Consuming Excess Energy Due to Sand and Grit? Emerging Technology Can Help You Find Out

Happy Easter

Subscribe

Get news delivered straight to your inbox the day it gets published."*" indicates required fields